ANCIENT EGYPTIAN MACHINING

4 Oct 1999

Posting by engineer Chris Dunn to Atlantis Rising

My original assertions regarding ultrasonic machining were based on what I considered to be a very detailed and accurate description of the Valley Core artifact by Sir William Flinders Petrie. Petrie was known for his meticulous work, was the father of modern Egyptology, and his description of the artifact was so detailed and thorough, I assumed that it was correct.

In Giza: The Truth, Lawton and Ogilvie-Herald claim that Petrie was mistaken and point out that physical and photographic detailed examination of the artifact in question by two other researchers, Reid and Brownlee, show that the spiral groove, the principle characteristic of the piece that leads me to suggest that ultrasonics was used, was not spiral but circular.

Until I have the opportunity to perform a detailed inspection of the piece, which requires more than mere visual scrutiny, I am forced to defer to the observations of Reid and Brownlee. Nevertheless, even in so doing, I have questions about their observations if they are basing them on the photograph in Lawton/Herald's book. What we have is a photograph that shows the frustrum of a cone (the Valley Core) with grooves cut into it. As you know, Eddie, as well as any other machinist and engineer who work in the aircraft industry, visual observations of features on a cone are dependent on your angle of view, as well as the attitude of the cone.

If the cone is lying down along the length of its diameter, the surface you are looking at is tilted at the combined angle of the cone, and, depending on your angle of observation, a concentric groove cut into the diameter could appear to be an ellipse. Then if the cone is tilted to the left or the right, any feature you may be observing on its surface will be tilted also.

The photograph in Lawton/Herold's book shows the Valley Core in black and white and it is tilted on an angle. The grooves cut into the diameter of the cone have the appearance of being horizontal, which would give a casual observer the impression that they were not spiral. I took the JPG of this photograph, kindly sent to me by Nick Annies, and brought it into my graphics program. I then constructed a frame around the core and rotated it until it was squarely positioned within the frame.

The grooves observed under these conditions appear to definitely be spiral.

This is why I have only "suspended" any assertions on ultrasonic machining. I need to do a personal on-site measurement of the groove to satisfy myself as to who is correct - Petrie, or Reid and Brownlee.

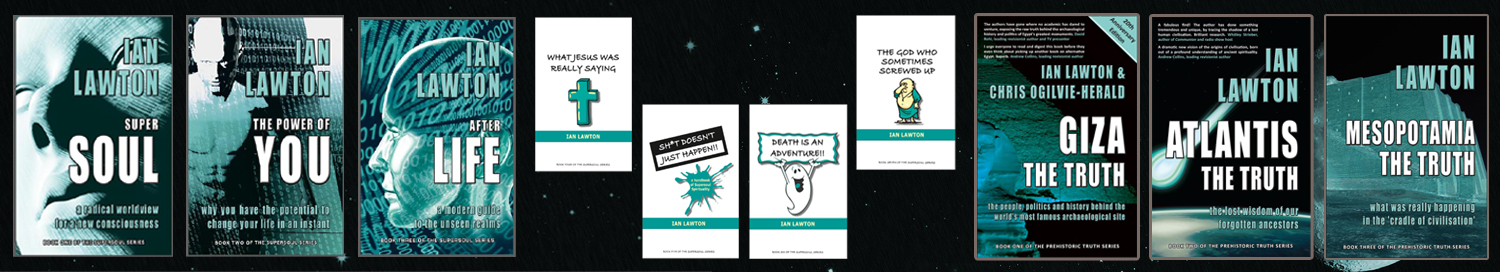

Do I recommend the book? Certainly! I found, for the most part, that it was well written, and the authors had gone to great pains to bring forward esoteric information from early researchers. After reading Giza: The Truth, my first instinct was to write a rebuttal. My publisher asked that I do not respond to their treatment of my work. Nevertheless, I promised Chris Ogilvie-Herald a response, and this is as good a time and place as any to fulfill that promise.

In this book the authors have gone to great length and worked very hard to support the orthodox view of Egyptology. In the process, they seem to have adopted the attitude and style of some of the contributors to the sci.archaeology newsgroup on DejaNews. (I'm saying that from personal experience.) I don't totally blame them for the presumptuous title, for the most part publishers have control over those things, and I'm sure that they believe what they have written is true to the best of their knowledge.

In their treatment of The Giza Power Plant, Lawton and Ogilvie-Herald resort to name calling, and claim that I am suffering from "millennium fever." Notwithstanding the fact that I started my book in 1977 - and they in 1997? The truth is that I had started writing about the Giza Power Plant theory before I had read Petrie's work. Much of my original research on the power plant theory was drafted before I wrote anything about advanced machining. My original ideas came from Tompkin's book, and it was while working through his bibliography that I came across the gold-mine of information contained in Petrie's Pyramids and Temples of Gizeh. So I have been suffering from "millennium madness" for over 20 years.

What offends me is that, in typical orthodox style, following the ad hominem statement in this book, the reader is treated to a simplistic dismissal of a very detailed and complex engineering subject. My analysis of the Great Pyramid, they say, fails to consider "context" and is summarily dismissed without any alternative explanation for the innumerable mysteries of the Great Pyramid for which my book proposes legitimate and realistic answers.

What is the context they are speaking of? It is cultural context. The context of a culture that is obsessed with death and the afterlife. I have failed to uphold theirs and Egyptologist's requirements that researchers consider the body of knowledge that has been painstakingly assembled about this subject. In the context of a tomb, though, there is no answer for the many features and anomalies of the Great Pyramid. Only when considered in the context of a scientifically engineered device - a machine - do we begin to understand its complex design. It is my opinion that in terms of explaining the pyramids, the engineering context has more legitimacy than a cultural context. The litter we may find around the Hoover Dam describes a particular cultural context, but not necessarily the whole picture. When interpreted within an engineering context, the Hoover Dam broadens the view of the entire culture.

As I stated in my book. Any theory that purports to explain the Great Pyramid has to answer ALL the previously unanswered questions. Every detail must be explained. Every design feature. And the explanation must make sense. The elements must fit together.

We must not lose sight of the truth because of ego. If I am wrong, I will willingly admit it. But it must be proven to me by more than a simplistic argument such as what is offered in Giza: The Truth. The context within which any society lives is the context of survival and work. An obsession with death grows out of this principle context. It is not the main event. Within the context of work we see the results of the application of tools. When scholars seek an understanding of what tools were used to build the pyramids, why do they look to Egyptologists? Were they involved in the original work? Are they involved in such work today?

One last point. In life we have to sell or eat our products to survive. The products that support my family and me are manufactured items. The product that supports Egyptologists is information that they have spent years studying and understanding. If any of us are suddenly unable to explain or sell our product, we must eat it to survive. The product sold by academics has been devalued recently, and they are nervous because they are unable to explain the true nature of the pyramids in a way that satisfies a technologically astute population.

19 Oct 1999

Response posted by IL to Atlantis Rising

As one of the co-authors of "Giza: The Truth", I thought it might be appropriate to make a few points on Chris Dunn's posting of the 4th October to help clarify some issues…

Ref "Drill core No 7", Reid and Brownlee took this photograph themselves, and accordingly were able to spend considerable time examining the core from all angles and in detail. In any case, far more significant is Chris' own admission in his book that ultrasound machining operates primarily via a pounding and not a rotational action, which is what makes the supposed feed rates displayed on the core such a red herring in the first place. Rather than injecting further red herrings, it would be useful if he could elaborate on how he resolves this major dichotomy. On this note it is also fundamental that Brownlee asserts that modern ultrasound cores tend to be totally free of striations.

Ref our supposed suggestion that Chris was "inspired" by the work of Hancock and Mckenty, this was merely "poetic licence" and no great point of significance was intended - as can be seen by the fact that it is Chris' work which receives all the subsequent attention, and not the others'. Nevertheless we are happy to take his reminder of the origins and motivation for his work on board, and adjust our wording accordingly for the next edition of the book.

Ref our supposed "simplistic dismissal of a very detailed and complex engineering subject", we can quite understand Chris being upset at us bracketing him with others who we, clearly somewhat tongue-in-cheek, suggest are suffering from "millennium madness", but it should be quite clear that we attempt to treat his theories on machining with considerably more respect than his general theory about the "Giza Power Plant". This is given only a cursory mention along with other similar theories. However, to suggest that we provide only a simplistic dismissal with no explanation of the "innumerable mysteries of the Great Pyramid" is, I think, stretching the point. If Chris has read all the early chapters, and the relevant appendices which must also be read in order to obtain a full understanding, then I find it impossible to believe that he or anyone else can suggest that we fail to properly evaluate all the supposed anomalies of the Great Pyramid, or to prove that all have a simple explanation within a funerary and ritualistic context - with the possible exception of the "air shafts" which we believe do remain something of an enigma but still have primarily a ritual explanation.

Finally, it may be useful to once again emphasise, since there seems to be a suggestion that we have somehow been "retained" by the orthodox camp, that we initially felt that many of the alternative theories probably were superior to the orthodox, and it was only when we conducted our full research programme for the book that our opinions changed on most issues as a result of our findings and nothing else. As other researchers have delighted in pointing out, we are relative new boys with no official qualifications in Egyptology, so it should I think be clear that we had, and have, no axe to grind either way. Moreover we do leave our minds a little more open to unorthodox possibilities than most Egyptologists where we believe the evidence merits it, for example as regards the elevation of the most massive temple blocks.

I hope this provides some brief but useful clarification.

23 Oct 1999

Response posted by Chris Dunn to Atlantis Rising

Thank you Ian for your response.

Ref "Drill core No 7". Yes, I have heard this argument before, and phrased in almost the exact same way. Deja-Vu. Let me address it this way. I am sympathetic to those who see a dichotomy with how my explanation of how ultrasonic machining explains the features of the core and, therefore, reject the notion. In fact if there was such a disconnect within my own understanding of the technique described I would reject the notion also. As I tried to explain the technique on the DejaNews sci.archaeology newsgroup several years ago, and now find myself again faced with the same arguments, I will take the responsibility for not explaining it sufficiently the first time and have another go at it.

(I have developed an understanding of manufacturing over a 38 year period, and I sometimes forget that some of the simplest concepts may be foreign to those who have no experience in this field. I should add, though, that I have not had any problems explaining this technique to machinists, toolmakers and manufacturing engineers. Therefore, I would ask those who do not have any manufacturing experience to read and attempt to understand what I have to say without the assumption that I am wrong simply because the conclusion does not fit within their own particular belief system.)

First of all, let us discuss Reid and Brownlee's findings. To tell the truth, I am somewhat embarrassed that I do not have a personal inspection of the core on record. I am caught flat-footed by their assertions that the grooves on the core are not spiral, as Petrie described, but individual grooves that start and end at the same point. With Reid and Brownlee being the most recent observers of this artifact, I will take them at their word and suspend my own speculations of ultrasonic machining until I have had the chance to check their finding. I admit negligence for not verifying the reports of earlier researchers such as Petrie and Lucas before writing my book, and I am quite willing to make any fact-based changes as necessary in future editions of the work.

Though Reid and Brownlee discredit Petrie's observations, on page 88 in Ancient Egyptian Materials and Industries by A. Lucas, we read a description of cores with as many as 17 equidistant spiral grooves (see also The Giza Power Plant page 86). As both Petrie and Lucas made their observations many years before I came along with my "alternate" views, I can reasonably argue that their observations were without prejudice, and they were not trying to prove, or disprove, a point. Moreover, I have personally examined holes in granite at Abu Ghurab that display spiral grooves, so it didn't occur to me to question the observations of Petrie or Lucas. Being remiss for not physically examining drill core 7, I am left with no option but to question Reid and Brownlee's observations along with Petrie and Lucas and prepare for a trip to London in November to inspect the artifact myself.

In the meantime, I am compelled to explain, in detail, why I determined that ultrasonic machining was the only machining method that satisfied the evidence that was described by Petrie.

When Ian writes, "far more significant is Chris' own admission in his book that ultrasound machining operates primarily via a pounding and not a rotational action, which is what makes the supposed feed rates displayed on the core such a red herring in the first place," I read into the sentence an artful and sophisticated rebuttal of a reasonable and simple manufacturing technique. Let us try to understand what this sentence means.

"Chris's own admission in his book that ultrasound machining operates primarily via a pounding and not a rotational action..."

There is nothing to admit or deny. It is the nature of the beast. Ultrasonic machining is a discrete oscillatory abrasive process. Correct me if I'm wrong, but the way I read this, Ian is assuming that if there is a pounding action for the removal of material, there is no need to be looking at or describing a rotational action.

"Which is what makes the supposed feed rates displayed on the core such a red herring in the first place."

My understanding of what these sentences mean is that the feed rate described by Petrie on the core, and which my theory of ultrasonic machining relies on, may be a red herring - a false clue. Before we go further, let us look at another statement.

"Rather than injecting further red herrings, it would be useful if he could elaborate on how he resolves this major dichotomy."

Right. Well, using Petrie and Lucas's described evidence, the "dichotomy", or separate parts to this process, are actually integral and depend upon each other for the process to work. Before continuing with ancient Egyptian artifacts, though, let me describe a modern technique of machining that is little known or used in most machine shops today. Now remember, we are not in ancient Egypt now, so you can accept what I am saying as demonstrated fact. Remember also that there are other readers of these posts who are my peers - engineers, machinists and toolmakers. So I'm not trying to pull the wool over your eyes.

We know that copper can't cut granite, right? Well, how do you get a piece of copper to tap a hole - or cut an inside thread - in a piece of hardened tool-steel?

The answer is electrical discharge machining (EDM). EDM discretely removes conductive material by creating a controlled short between an anode (tool) and a cathode (workpiece). Dielectric oil flushes the waste material away. The copper or graphite electrode actually burns the material leaving behind an impression of its shape. The round copper rod has a helical thread cut into its outside diameter, like a bolt. An assembly with a nut is attached to the ram platten of the machine. The copper "bolt" is then rotated in a clockwise direction. With each rotation of the "bolt" it comes closer to the workpiece. When the "bolt" is a few microns away from the workpiece, electrical discharge occurs. By continuing to thread the "bolt" through the nut while maintaining electrical discharge from the steel, the geometry and feedrate of the "bolt" is burned into the steel, resulting in a spiral thread. Properly done, the EDM "tapped" hole is precise and effective.

I draw on this analogy to explain my theory on ultrasonic machining. The ultrasonic pounding action provides discrete material removal; however, without some force or mechanism to advance the tool into the workpiece, the tool would be pounding only fresh air. There has to be a means by which pressure is applied to the workpiece. I proposed, based on Petrie's observations of an impossible conventional feedrate, that the pressure was provided by the screw and nut method. With only the screw and nut and no pounding action, we will advance the tool as far as the workface and go no further. The elements are separate but dependent on each other; therefore, there is no "major dichotomy" and no "red herring."

"On this note it is also fundamental that Brownlee asserts that modern ultrasound cores tend to be totally free of striations."

I heard this argument on DejaNews, too. In a perfect world, all machined surfaces would be free of tool marks. If you were observing holes ultrasonically drilled into expensive optical components for NASA or the ESA, there would be no striations. Most ultrasonic machines plunge directly into the material without rotating the tool. Most EDM machines do the same. There are exceptions to both. There are also exceptions to the requirements for smooth striation-free machined objects. Machinists and toolmakers have been known to "crowd" or force the tool into the workpiece in order to speed production. In some instances, depending on the tool, it is beneficial to "crowd" the workpiece as it has a self-dressing effect. Take grinding, for instance. A grinding wheel can become clogged with the material it is removing which slows down the grinding process. A technique for overcoming this it to force the wheel across or into the material to the point that wheel breaks down and wears. This assures that the clogged material is removed and the tool can continue to cut efficiently.

My understanding of the scientific method of inquiry is that a hypothesis must be fact-based and provide answer for all the known evidence. I was looking for a method that explained all the characteristics of the core, which included a taper on the hole and core, indicative of wear of the tool. Clyde Treadwell of Sonic Mill described an ultrasonic process where the tool would leave a spiral groove while being drawn out of the hole, but the tool was spinning, and the groove was the result of the eccentric rotation of the tool. I concede that if a spinning tool can create these characteristics, then there is no need to resort to ultrasonic machining. I was persuaded by a variation of the ultrasonic method because of the report that the "spiral" groove was cut deeper through the quartz than the felspar. Right or wrong I was basing my analysis on my own personal experience with machining materials that were not homogenous in their physical makeup. The harder material tends to be more resistant to tool pressure than the softer material.

The foregoing are reasons why I proposed ultrasonics as an answer. I have always maintained that if another method was forthcoming that would answer all the characteristics noted, and that method was simpler, then Occam's Razor, where all else being equal the simplest explanation is probably the correct one, would take precedence.

I hope to be in London within the next 4 weeks to examine drill core #7, after which, ultrasonic machining will either be taken off the table or it will remain a possibility. In the meantime, there is much more in my book we could discuss regarding machining. What about the precision and geometry of the contoured blocks on the Giza Plateau? Or the boxes in the Serapeum and Khafre's pyramid. A detailed description of these artifacts can be found in The Giza Power Plant.

25 Oct 1999

Response posted by IL to Atlantis Rising

Many thanks for constructiveness of last reply - now I think we are getting somewhere, at least on the machining front.

The major point I would once again like to emphasise, because I think we may still be clouding it, is the following: I have always understood that you allow for the fact that any rotational effect in the drill cores may be down to the feeding rather than the cutting mechanism, but surely my point still stands that any rotational striations caused by a "feed-not-cut" mechanism cannot be used to judge the basic speed of cut - and I still maintain that it was this very possibility which appeared to excite both Petrie and yourself in the first place. It is in this sense I have dubbed it a red herring, but if I am being unfair please elucidate further.

Also, with ref to the quartz layers being cut deeper than the feldspar, may I remind you of Harry Brownlee's comments as quoted in "Giza: The Truth" (p. 219): he argues that "when a diamond or corundum-tipped tubular drill meets a region of quartz which is embedded in the softer feldspar, some of the quartz may be ripped out, depending upon the crystal's orientation and grain direction with respect to the tool angle". Any comments on this as an explanation?

25 Oct 1999

Response posted by Chris Dunn to Atlantis Rising

You are not being unfair, Ian, just inexact. It sounds, though, like we don't have too far to go before we understand each other.

You are correct in saying that rotational striations caused by a "feed-not-cut" cannot be used to judge the basic speed of cut, if by speed of cut you mean the speed of the drill. Technically, though, "feed-not-cut" is incorrect, for without feed there is no cutting action. Likewise, it cannot be used to explain the time it took to drill the hole. All the striations tell us, if they are spiral around the core, is the feedrate. I will take the blame for confusing some people on this issue. I had used the word "faster" rather than "greater" in my original article and compared the ancient Egyptian feedrate to that of modern drilling of granite. I said it was 500 times faster. My mistake. Greater was what I meant, not faster. In fact, the drill was in all probability turning quite slowly.

What "excited" Petrie and myself, was what appeared to be a phenomenal feedrate for drilling into a solid piece of granite regardless of the speed with which the drill turned. For every 360 degree turn of the drill, the drill sank .100 inch into the material. This is what we were faced with. What method could perform such a feedrate into solid material. These striations are not red herrings. For determining feedrate, they are as relevant a clue on ancient artifacts as they are on modern ones. The striations on a bolt are created in a similar way. They are not red herrings. They are a critical characteristic not only to the process, but the product also.

I have no argument with Brownlee's observations on the quartz being ripped out of the felspar thereby leaving an indentation. I totally agree with him. A close examination of the core under microscope should determine whether the quartz was ripped or abraded. And from my corner, if the striations on the core are not helical the entire argument becomes moot.

6 Dec 1999

Email response from IL to Chris Dunn

Two things occur to me as a result of your last posting:

First, although I am not a trained engineer I am sufficiently intelligent to realise that feeding and cutting are essential and complementary processes in drilling! Nevertheless, you have now amended your explanation of the supposed spiral grooves to suggest that the feedrate was "greater" rather than "faster", and that you do not think the drill bit was rotating rapidly (whichever method was used). I assume that by this you mean that the actual rate of cut (i.e. the amount of material removed in a specified period of time) must have been phenomenally high in order for the feed rate (as supposedly indicated by the distance apart of the spiral striations) to be so high (neither of which suggest anything about speed of rotation). If this is the case, then I accept that my observations about "feed-not-cut" rates appear to be inaccurate - except with the rider that I did not fully elucidate what I meant and for this omission I apologise. The factor I omitted (albeit that it is one which we bring up in "Giza: The Truth") is the possibility that even IF the striations were spiral (which in Reid and Brownlee's view they are not on this core) and not random horizontal patterns, these would have been caused more likely by the bit continuing to rotate as it was WITHDRAWN from the core. This would render them irrelevant as an indicator of either feed or cut rate.

Second, in your posting of 23 Oct you say: "Clyde Treadwell of Sonic Mill described an ultrasonic process where the tool would leave a spiral groove while being drawn out of the hole, but the tool was spinning, and the groove was the result of the eccentric rotation of the tool. I concede that if a spinning tool can create these characteristics, then there is no need to resort to ultrasonic machining. I was persuaded by a variation of the ultrasonic method because of the report that the "spiral" groove was cut deeper through the quartz than the feldspar." Then in the more recent one of 25 Oct you say: "I have no argument with Brownlee's observations on the quartz being ripped out of the feldspar thereby leaving an indentation. I totally agree with him. A close examination of the core under microscope should determine whether the quartz was ripped or abraded." Although we must await your own report on the drill-core, presumably you are agreeing that if it was ripped then your ultrasonic machining theory becomes redundant even by your own admission?

I trust you will respond to these issues in your next posting.

29 Dec 1999

Response posted by Chris Dunn on his own web site, plus abbreviated version of the report of his visit to the Petrie Museum

Please don't think I have ever doubted your intelligence, Ian. If anyone can recognize intelligence, I can. I have a great respect for intelligence. I sometimes wish I could exercise more of it myself. (And I'm still smarting over the invitation to leave my local Mensa group so that I didn't dilute the gene pool.;-)

I understand you are not a trained engineer, though, from what you wrote in your previous posts, I didn't realize that you understood that feeding while rotating was necessary to achieve cutting when drilling. A simple misunderstanding on my part, I'm sure.

Your statement, "you have now amended your explanation of the supposed spiral grooves to suggest that the feedrate was "greater" rather than "faster", and that you do not think the drill bit was rotating rapidly (whichever method was used)," totally misrepresents my position. I have not amended my original thinking on the subject of feedrate or what I intended to say. I have rephrased my explanation not amended it. I never did think that the drill was rotating rapidly, and if you would go back and read chapter four in The Giza Power Plant: Technologies of Ancient Egypt, you will find that what you describe as a recent amendment, was, in fact, rephrased and published over a year ago.

With respect to the rest of your post, I am happy to respond with my report on my research at the Petrie Museum University College London [see below].

[The following is an abbreviated version of Chris Dunn's Report of his and Nick Annie's visit to the Petrie Museum to inspect drill core No. 7 on 15 Nov 1999; for the full report and photos see http://www.gizapower.com/petrie/chris5.htm]

…

Before going to London, I had a long conversation with Roger Hopkins, the stone mason who appeared with Mark Lehner on 'This Old Pyramid' and 'Obelisk.' He told me that another Obelisk documentary was produced this year in which Dennis Stocks, a master stone mason, demonstrates core drilling in granite using a copper tube, sand, and manpower - a method that is accepted by Egyptologists as the true method the ancient Egyptians used. Though Roger was initially supportive of my ultrasonic drilling theory, he tempered his original enthusiasm by stating that, while he and Stocks disagreed as to the methods of drilling the rock, he was convinced that it could be done using primitive methods. Other characteristics of Egyptian granite artifacts that we discussed I will address later.

Roger told me that the film is in the can, but I couldn't get any details of what kind of core was produced, except that it is similar to Petrie's core. A recent posting to the Atlantis Rising forum on Gizapower by Mikey Brass states that Stocks had produced such a core, but I am still waiting for details about what kind of grooves were produced in it using his methods.

…

Then it came time to inspect the infamous core #7. Although I had talked and written about this core for over 15 years, this was not a reverent visit to a holy relic that one might expect. I was not especially breathless with excitement to take the artifact into my latex-gloved hands. Nor was I impressed with its size or character. To tell the truth I was profoundly unmoved and disappointed. With the old Peggy Lee song "Is That All There Is?" bouncing around in my head, I peered at this insignificant looking piece of rock which had fuelled such a heated debate on the Internet and in living rooms and pubs across the globe. I was thinking to myself as I looked at the rough grooves on its surface, "How do I make sense of this?" And, "What was Petrie thinking about?

…

Not a word passed between us as I formulated in my mind my ultimate confession to the world. I had made a huge mistake in trusting Petrie's writings! The core appeared to be exactly as Reid and Brownlee described it! The grooves did not appear to have any remote resemblance to what Petrie described.

…

I first checked the width between the grooves using the microscope. At this point I was certain that Petrie was totally wrong in his evaluation of the piece. The distance between the grooves, which are scoured into the core along the entire length, was .040 - .080 inch. I was devastated that Petrie even got the distance between the grooves wrong! Any further measurement, I thought, would be just perfunctory. I couldn't support any theory of advanced machining if Petrie's dimensions of .100 inch feedrate cannot be verified! Nevertheless, I continued with my examination.

The crystalline structure of the core under microscope was beyond my ability to evaluate. I could not determine as surely as Petrie did that the groove ran deeper through the quartz than the feldspar. I did notice that there were some regions, very few, where the biotite (black mica) appeared to be ripped from the feldspar in a way that is similar to other artifacts found in Egypt. However, the groove passed through other areas quite cleanly without any such ripping effect. Though again, I support Brownlee's assertions that a cutting force against the material could rip the crystals from the feldspar substrate.

I then measured the depth of the grooves … [which were between] .002 and .005 inch. (Actually, because there were clearly discontinuities in the groove at some locations around the core, the actual measurement would be between .000 and .005 inch).

Then came the great question. Was the groove a helix or a horizontal ring around the core? I had deferred to Reid and Brownlee's assertions that they were horizontal and I was, at this juncture, painfully assured that it was the correct thing to do. It was Petrie's description of the helical groove that made Core #7 stand apart from modern cores. It was one of the principle characteristics upon which I based my theory of ultrasonic machining. But what I held in my hand seemed to support Reid and Brownlee's objections to this theory, for they said that the core had a similar appearance to any other core one may produce in a quarry.

I had rejected my initial plan to fixture the core and rotate it around its central axis to check for a helix. The fixture would have taken time and material to make and, though I had a willing toolmaker, Gary Bryant, to manufacture the fixture, I had opted for a cheaper, more primitive, though equally effective, method. The white cotton thread was the perfect choice to inspect for a helical groove. Why not use a thread to check a thread!

I carefully placed one end of the thread in a groove while Nick secured it with a piece of Scotch tape. While I peered through my 10 X Optivisor, I rotated the core in my left hand, making sure the thread stayed in the groove with my right.

The groove varied in depth as it circled the core, and at some points there was just a faint scratch that I would probably not have detected with my naked eye. As the other end of the thread came into view, I could see that what Petrie had described about this core was not quite correct.

Petrie had described a single helical groove that had a pitch of .100 inch. What I was looking at was not a single helical groove, but two helical grooves. The thread wound around the core following the groove until it lay approximately .110 inch above the start of the thread. Amazingly, though, there was another groove that nestled neatly in between!

I repeated the test at about 7 different locations on the core with the same results. The grooves were cut clockwise looking down the small end to the large - which would be the top to bottom.

In uniformity, the grooves were as deep at the top of the core as they were at the bottom. They were also as uniform in pitch at the top and bottom, with sections of the groove clearly seen right to the point where the core granite was broken out of the hole.

These are NOT horizontal striations or rings as trumpeted in Giza: The Truth, but helical grooves that spiralled down the core like a double-start thread.

Petrie is vindicated. To say I am happy about that would be an understatement.

To replicate this core, therefore, the drilling method should produce the following.

* A clockwise double helical groove from top to bottom with a .110 - .120 inch pitch.

* The groove should be between .000 - .005 inch deep.

* A taper from top to bottom.

* Some ripping of the quartz is acceptable

It seems ironic to me that while Reid and Brownlee were insisting that these grooves were horizontal rings, they were also suggesting a theory if it was found that the groove was spiral. Why would they do that? If the grooves were as their expert testimony claimed them to be, why bother coming up with another theory in case they were not? Could it be that they came to their conclusions after examining only a photograph? Perhaps they will be forthcoming with more details of their methods and instruments for inspecting the core in subsequent posts.

With respect to Reid and Brownlee's "fall-back" argument for the creation of the "in-case-they-really-ARE-spiral" grooves, it does not survive a simple test to see if it lies in the realm of physical possibility. Certainly scratches could be made along the cores and hole as a rotating tube-drill was being removed while it was spinning, but not to the depth of .005 inch! Their theory of slap in the bearings, which allowed a spinning tool to cut the groove, is a theory that collapses under close scrutiny. Let me explain the last step in my research to date.

I walked out to the toolroom last week and talked to a toolmaker, Don Reynolds, who was working on a surface grinder. I asked him if he had a sharp diamond wheel dresser. (These are used to dress carborundum and other types of grinding wheels.) He had one that was barely used with a nice sharp point. (These industrial diamonds are set into a steel shank, which are then fixtured so as to sit on a magnetic chuck.) I asked him how deep a groove he thought he could scratch into a piece of granite with the diamond.

He said, "Let's find out!"

We walked over to a granite surface plate while I jokingly admonished him not to try it on the work surface. He pressed the diamond point into the side of the plate. Bearing down with all the weight he could throw behind it, he scoured the side of the plate with a scratch about 4 inches long.

We both felt the scratch. "How deep would you say that is?" I asked.

"Oh, between .003 - .005 inch." He said.

"Let's check it out then!" I said.

Don fixtured an indicator (clock) gauge in a surface gauge and zeroed the fine needle point on the surface. As he passed it over the groove, the point dropped into the groove and the dial read only .001 inch.

Why am I telling you this?

* Reid and Brownlee's theory relies on centrifugal force to cut the groove, as the drill is being withdrawn and passing over a widening gap, and to achieve greater centrifugal force, the drill would need to spin faster.

* There wouldn't be sufficient lateral force to cut a groove in granite to a depth of .001 inch, let alone .005 inch! It is a simple as that.

* With a spinning drill shank that has the freedom to roam inside an oversized bearing, the drill will seek the path of least resistance, which is away from the granite. In other words, it would push away from the granite, and with Reid and Brownlee's theory, there is plenty of room for it to move.

* Petrie's observations were quite valid when he claimed that this was not a viable means of creating the groove, because of a build-up of dust between the tube and the granite.

With respect to Reid and Brownlee's assertions that the grooves were not spiral. They have been proven wrong. I am happy that Petrie is vindicated, but I find it shameful that his meticulous research was contradicted to further the agenda of the orthodox church. In my view, Lawton and Ogilvie-Herald have succumbed to some forceful arguments against the advanced machining theory and have accepted them uncritically because they lack the expertise and experience to formulate their own educated opinion. This is not the balanced treatment they claim to have taken.

If it were my agenda to discredit a theory such as mine, I would probably seek out my own experts and charge them with the responsibility of doing their own analysis. I would select the weakest argument where the evidence is second-hand. Of course, I would tell them why I was sending them on this errand, and I might interject my own beliefs regarding the subject. Armed with such prejudice, it is easy to be wrong on such an artifact if you are only studying a photograph or image on a computer screen - or just holding it in your hands not believing such a spiral exists in the first place. Ogilvie-Herald and Lawton most likely took Reid and Brownlee's report with satisfaction and had every reason to believe them because what they saw on their computer screens, supported their mission in writing their book.

But, as my Father used to say, "Believe none of what you hear and half of what you see!"

11 Jan 2000

Email response from IL to Chris Dunn

I read your report with great interest. Although various people we have consulted have expressed doubts about the methods you used to verify the spiral grooves on the core, and although Reid and Brownlee definitely intend to re-inspect it to check your claims, for the moment I see no problem with us continuing on the working assumption that the core does display spiral grooves. So now we come back to the critical issue of whether or not these could have been created as the drill bit was withdrawn, which would then tell us nothing about the rate of cut. Certainly in your book, and in all the correspondence we had before your site visit, you accepted this as a possibility (witness your quoting of Clive Treadwell etc). Clearly you are now suggesting, as a result of your new research, that grooves of up to .005" in depth could not be produced by this process because of insufficient lateral force. Reid and Brownlee certainly do not accept your arguments in this area, but they suggest, and I agree with them, that continuing to debate these issues on a theoretical level suffers from diminishing returns. They intend to continue their research by practical experimentation, and as always we can only await the results. However I think it behoves both yourself and them to investigate the work of Denys Stocks in this area.

In any case, I am still unclear about what conclusions your additional research allows you to draw. You have stated previously that the primary aspect which made you consider ultrasound was the fact that the quartz was cut deeper than the feldspar, but that you now accept Brownlee's suggestion that this may have been caused by ripping. I see nothing in your latest report that makes a definitive judgement on this issue. So, in your view, is the ultrasound solution now totally vindicated, and if so what is the definitive line of reasoning?

I have deliberately tried to respond to the "constructive" element of your report first, so that those people monitoring this discussion who don't like bickering can stop reading now. However you make a number of less constructive suggestions in your report to which I must, unfortunately, respond.

It seems ironic to me that while Reid and Brownlee were insisting that these grooves were horizontal rings, they were also suggesting a theory if it was found that the groove was spiral. Why would they do that? If the grooves were as their expert testimony claimed them to be, why bother coming up with another theory in case they were not? Could it be that they came to their conclusions after examining only a photograph? Perhaps they will be forthcoming with more details of their methods and instruments for inspecting the core in subsequent posts.

We have indicated to you already, and it should be quite clear from the photo credits in our book, that Reid and Brownlee did perform an on-site inspection. Since you did not bother to do so yourself until prompted by our work, and even then your initial impressions were exactly the same as theirs, this continual petty carping detracts from the real arguments, to noone's benefit. As to why they allowed for the possibility of spiral grooves in their explanation, we make it quite clear in the book that this was to allow for the possibility that there was some mistake in the identity of the core in question (like all of us, they have great respect for Petrie and did not wish to dismiss his evidence out of hand).

With respect to Reid and Brownlee's assertions that the grooves were not spiral. They have been proven wrong. I am happy that Petrie is vindicated, but I find it shameful that his meticulous research was contradicted to further the agenda of the orthodox church. In my view, Lawton and Ogilvie-Herald have succumbed to some forceful arguments against the advanced machining theory and have accepted them uncritically because they lack the expertise and experience to formulate their own educated opinion. This is not the balanced treatment they claim to have taken.

And I find it equally shameful that someone who has purported to welcome intelligent debate should be so ungracious - especially since up until now I had held our particular discussion out as a prime example of how opposed parties can move each other's understanding forward if they stick to rational argument. I will repeat to you something I have been forced to say to both Robert Bauval and John Anthony West. If you care to check with our publishers you will find that the original synopsis for our book was strongly pro-alternative in theme (since before our detailed research was conducted we felt many of these arguments appeared persuasive), and it was on this basis that it was commercially accepted. It was never our intention to further the orthodox agenda, merely to report our findings without prejudice to some overall theme in each of the many areas we had to research. The fact that we ultimately came down on the side of the orthodox camp in most, but by no means all, of these areas, was purely a reflection of our detailed research and of the quality of the arguments we uncovered on both sides. We did not accept Reid and Brownlee's forceful (your own word) arguments uncritically, we preferred them to your own because at that stage of the game they were more logical and cohesive than those presented in your book. After all, you indicate quite clearly in the book that ultrasonic machining is only one possible solution pending further research.

Chris and I will be quite happy (apart from being obliged by integrity) to update our paperback edition to reflect your further research. However I would hope that in future you remember to appreciate that this constructive approach to debate not only renders your accusations of partiality and lack of balance totally ridiculous, but has also forced you to reconsider potential areas of weakness in your arguments and strengthen them. I would hope that any reasonable person would regard that as progress.

10 Feb 2000

Further email response from IL to Chris Dunn, including link to new work by the NOVA team suggesting conventional drilling methods were used

I notice that you have still not had the decency to post my last response to your paper on your website, while still giving your discussions with Ralph Ellis, which I instigated, top billing. Whatever your motives for this, and as a follow up to may last email to you, I strongly suggest that you take a look at the following web site, which describes with pictures some drilling work performed by the NOVA team and Denys Stocks on granite.

http://www.pbs.org/wgbh/nova/lostempires/obelisk/cutting.html

The final pictures seem at first sight to show drill cores with striations which are extremely similar to those on core No. 7.

I will of course be posting this communication on my own web site.

18 Sep 2000

Link to excellent pictures of Egyptian lathe-turned bowls.25 Sep 2000

Extracts from a paper prepared by Ivan Watkins postulating the use of focussed sunlight to machine Inca stonemasonry, that first appeared in Rocks and Minerals magazine in 1990.

6 Oct 2000

Email response from Chris Dunn to IL's of 10 Feb

With all due respect to Mr. Stocks for his capabilities and industry based on the photographs that have been shown and and what has been written, there is nothing from which to draw on opinion. Until the results of his labour have received the same scrutiny and analysis as Petrie's core #7 it would be premature to do otherwise.

30 Jul 2001

New analysis of the function of the 'Lobed Schist Bowl' in the Cairo Museum by Bill Kay

27 Jun 2003

Link to series of excellent papers by researcher Archae Solenhofen providing among other things excellent artistic and artefactual evidence of the use of copper bow drills and slabbing saws by the AE's.